RecoPhos and InduRed

Introduction:

Phosphorous is an essential element for all life forms and its exploitable deposits are getting scarce quickly. This and also the fact that phosphate mining and refining has severe negative effects on the environment and the production of vast amounts of dangerous wastes, will make it inevitable in the near future to recycle phosphorus from every suitable P-containing waste. Sewage sludge (coming from municipal wastewater treatment) is considered to be one of the most important alternative Phosphorus sources. In this sludge all of the phosphorus discharged by humans is concentrated and can, if properly collected and treated, be re-used completely. Its inorganic dry matter (=ash-content) has a phosphate content between 30% and up to 70% of the content of phosphate rock produced from natural phosphate ores. The aim of the RecoPhos project was to develop a completely new P-recycling process, which can avoid several of the known chemical-technical problems that are still limiting the possible success of phosphorus recycling. In the project, the process was developed using modelling and lab scale experiments. Using these results, the basic design of a pilot scale plant was carried out, a market study was performed and the environmental impact of the process compared with the status quo was evaluated in a Life Cycle Assessment study.

The RecoPhos process:

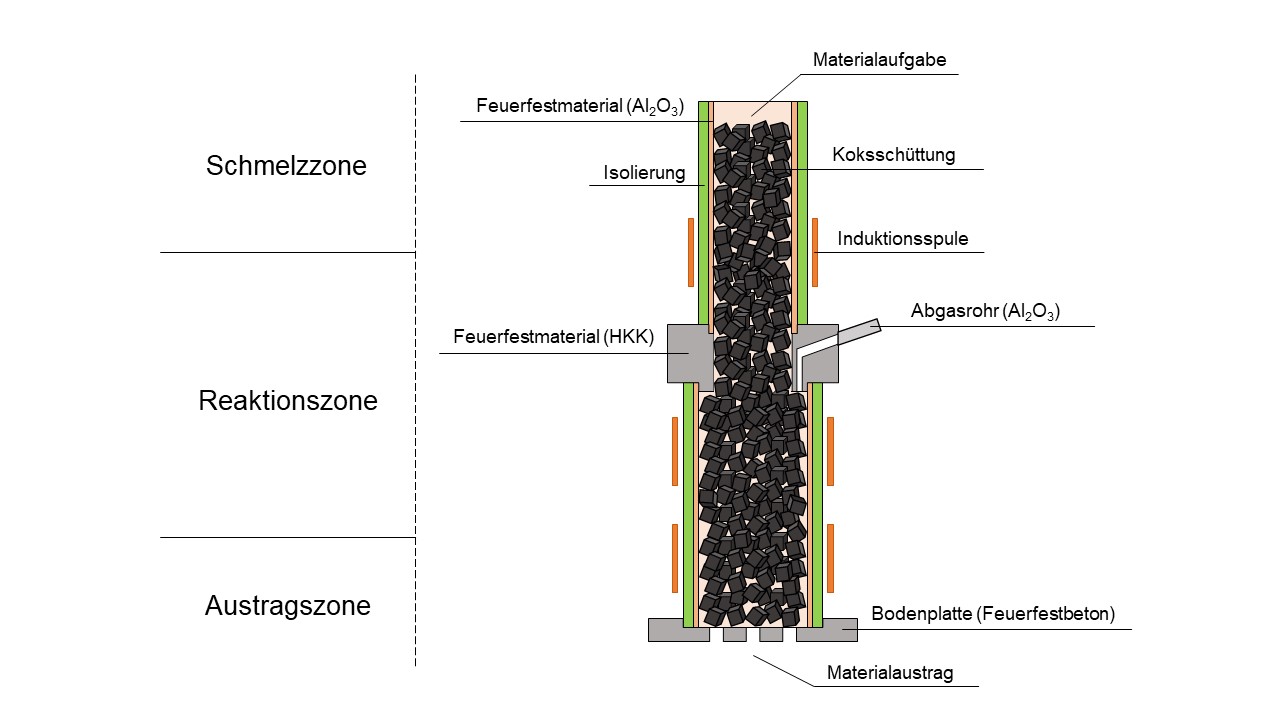

The principle of the RecoPhos process is the fractioned extraction of phosphorus and heavy metals from sewage sludge and its ash at high temperatures under reducing conditions. The core technique of the RecoPhos process is the so-called InduCarb reactor. The following summary reaction of Ca-Phosphate takes place in the inductively heated bed of carbon as illustrated schematically in figure 1.

![]()

Furthermore, all the other phosphates, like FePO4 and AlPO4 are reduced in the reactor.

Figure 1: The InduCarb reactor in the RecoPhos process

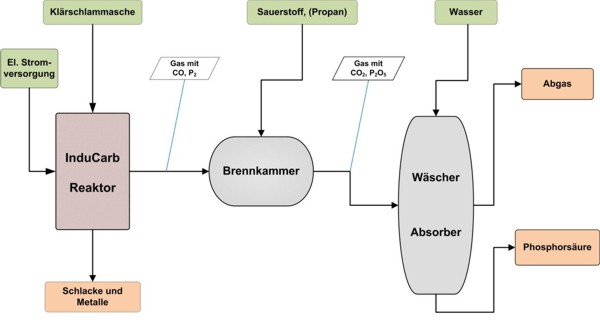

The produced reactor gas is quenched and in a subsequent scrubber phosphoric acid is produced.

Figure 2 shows a simplified process flow diagram.

Figure 2: Simplified overview flow diagram of the RecoPhos process.

The RecoPhos research project has received funding from the European Union Seventh Framework Programme (FP7/2007-2013) under grant agreement no. 282856.