WasteX

Explosion prevention in mechanical waste treatment facilities

In mechanical waste treatment facilities, such as plants for the production of substitute fuel, the input material passes through a series of processing units, where they get crushed to small pieces and separated. At each treatment step and transfer station a fine-grained fraction occurs. Combustible materials with particle sizes beyond 500 µm can cause dust explosions under certain conditions. In order to characterize the explosion behaviour of the occurring dusts in waste treatment facilities, samples from filter and deposited dusts from plant components were taken. The investigation of deposited dusts is necessary because the dusts can get dispersed in air again and give rise to a dust explosion.

Figure 1: Deposited dust on plant components

In order to classify the risk potential of the dusts occurring in mechanical waste treatment facilities and to identify the influencing factors on the explosion behaviour, dusts from different waste treatment facilities of different industrial partners are investigated and their explosion characteristics are studied.

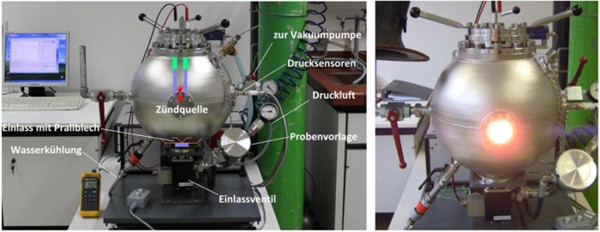

The laboratory studies to evaluate the effect of a dust explosion of an air / dust mixture are done in a 20-litre Siwek Apparatus, which was funded by the FFG (Austrian Research Promotion Agency) as well as the whole project.

Figure 2: 20-l Siwek Apparatus for the analyses of maximum explosion pressure, dust explosion class, minimum explosion concentration and limiting oxygen concentration

To expand the research area of safety engineering at the Chair of Thermal Processing Technology and to optimize the opportunities for experimental studies, the laboratory equipment was completed with an apparatus for the investigation of the minimum ignition energy (MIKE 3). This analysis instrument permits comprehensive and holistic safety relevant studies at the Chair of Thermal Processing Technology.

Figure 3: MIKE 3 Apparatus for the investigation of the minimum ignition energy

Analyses show that the explosion behaviours of dusts from various mechanical waste treatment facilities are well comparable with each other. The differences in the explosion characteristics are mainly caused by the inert fraction as well as the inhibition due to the content of coarse particles in the dust samples. Finally the objective of the project is to enable the prediction of the explosion behaviour of dusts from mechanical waste treatment facilities on the basis of influencing parameters, which are easy to determine.

The project partners are: